No shortcuts during our fibreglass boat building

There are absolutely no shortcuts during any stage of Evolution Boats’ construction process – all fibreglass is hand–laid for ultimate hull strength. Committed to excellence, safety, and quality, Evolution Boats enjoys the highest reputation for its unique design, unparalleled performance, and matchless construction.

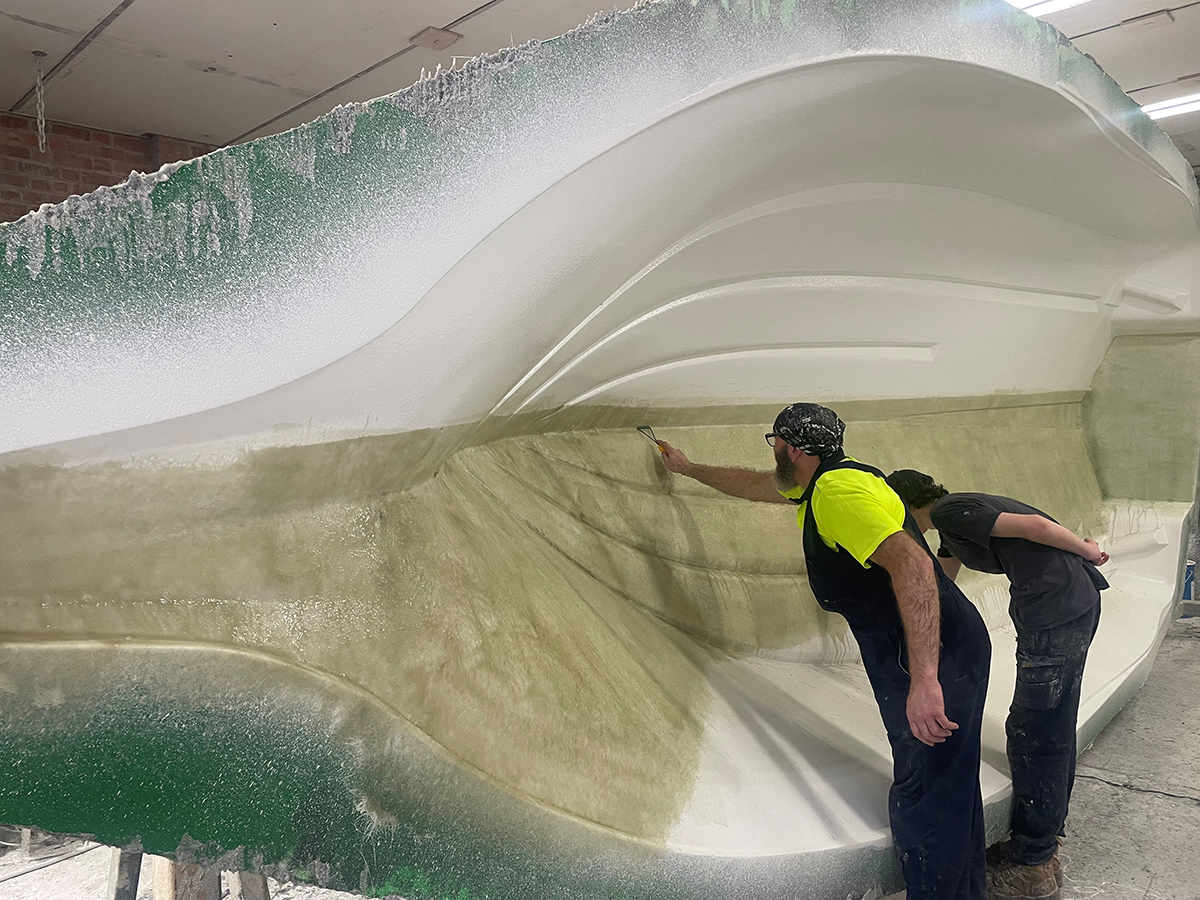

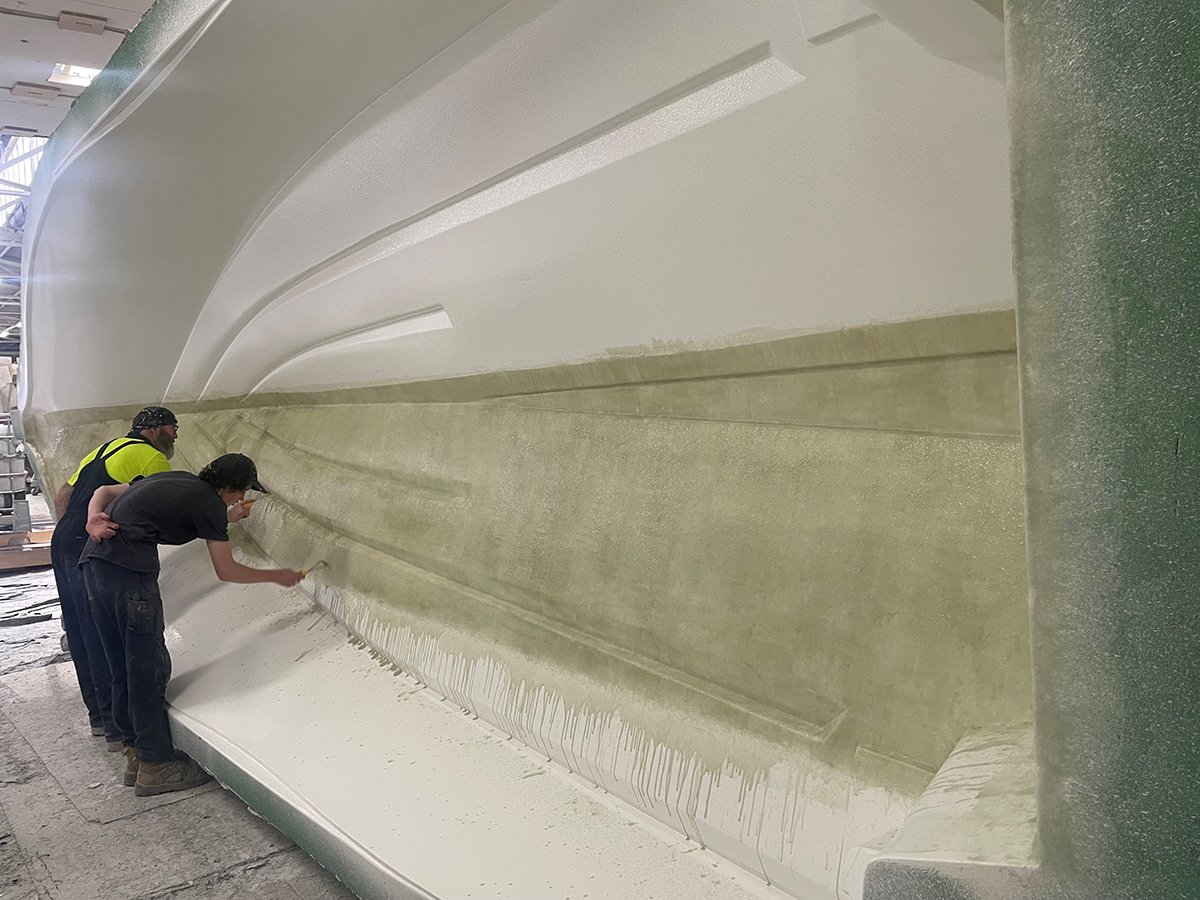

The following images show some of the stages in the construction of Evolution’s 550 and 650 series. These processes are applicable to all models in the range.

Watch the construction process

Australian-made, hand-laid construction

Hand–laid fibreglass construction is far superior to any other construction method. Evolution uses different-weight fibreglass mats and woven rovings to ensure a solid and consistent build, with the same process repeated for each boat. Hand–laying the hull prevents light spots of fibreglass and allows better quality control. It may be a slightly longer build time than other methods, but results in a superior quality laminate.

- Consistent construction methods

- Even fibreglass distribution

- Customer piece of mind

- Greater resale value

Fibreglass hull, smoother ride

Our Fibreglass hulls are designed with a great ride and stability at rest in mind. Evolution’s stand-out features are a wide beam, reverse chines and flared bow makes our hulls stand out from the rest.

Each hull has been hand laid with fibreglass matting. The gel coat is sprayed into the hull mold first. This is the first layer of fibreglass on the boat.

- Complex shapes giving a better riding hull

- Stability at rest

- Heavier construction giving a smoother ride

- Quieter riding hull

Fibreglass stringers, transom and floor for longevity

All Evolution boats now have fibreglass transoms and our long-established stringer system.

The hull stringers, floor, and bunks are assembled while the hull is still in the mold to ensure the hull keeps its shape.

- Longevity in mind

- No rot, no rust

- No wood all fibreglass

- Strong foundation

Foam filled hulls

Foam Filled Hull using a closed cell foam in the stringers and under the floor cavity. Filling the stringers and underfloor cavities with foam provides a stronger bond, a quieter riding hull, and safety.

- Aids buoyancy

- Noise reduction

- Ride comfort

- Safer, quieter, stronger

Deck assembly

Decks are prepared in a separate mold and many fittings are attached prior to joining the deck to the hull. This process allows for a more efficient fit-out and increased quality control.

The decks are designed for maximum functionality in a small area. Large dashes, spacious platforms for fishing, Rod Storage areas, and raised battery storage are found in each Evolution.

- User friendly

- Spacious design

- Practicality

- Plenty of storage

Fit out process

Floor covers are positioned over the floors to protect them during the fit–out process. This is when the windscreen, Polyethylene rotor molded fuel tank, stainless steel accessories, electronics, and other options are fitted. All upholstery is fitted during this stage

- All stainless fittings

- HDPE backed upholstery

- Quality accessories

- Wide range of factory fitted options

Get a Quote

Request more information on a range of our fibreglass offshore fishing boats.

Factory Tour

Take a tour of our factory located in Bayswater. See the fibreglass boat-building process yourself.